螺旋桨喷漆真的是画蛇添足吗?

Propeller paint is really gild the lily?

(有机硅防污涂料在船舶涂装中的应用)

(

Silicone antifouling paint application inship coating

)

今天刚刚上班,小徒弟跑过来:师父今天我看到船台的那条快下水的船很奇怪,好好的螺旋桨又是打砂又是喷漆。这不是画蛇添足吗?

Todaywhen I just to begin the work, the small disciple come to ask me: master, I sawthe berth of the quick launching ship is very strange, the good propeller is sandingand painting. This is not really gild the lily?

(照片里螺旋桨上做成了白色油漆)

(In the photo thepropeller made into white paint)

徒弟这哪是画蛇添足啊!这是在给螺旋桨喷涂有机硅防污漆。

Myapprentice, This is spraying coating a silicone anti fouling paint on thepropeller and not gild the lily!

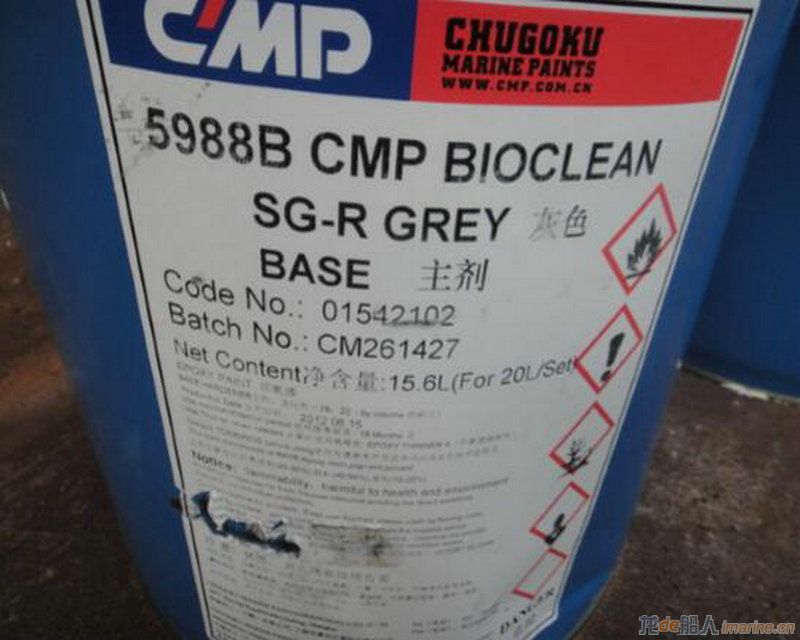

(上图的螺旋桨做了中塗化工涂料CMP公司的有机硅防污漆)

(Propeller made ofchemical coating of silicone antifouling painting made by CMP in the picture)

小徒弟有点蒙圈,不停的问。

Heis a little confused and still ask me.

螺旋桨不是铜的吗?

Isthe propeller not made by brass?

铜质螺旋桨一般不会生锈那为什么还要喷漆啊?难道螺旋桨也需要防污漆的保护?

Copperpropeller will not rusty why should we painting? Does the propeller alsorequire the protection of antifouling paints?

那螺旋桨上喷的是什么漆?

Whatkind of painting should the propeller use?

哪家油漆公司的漆质量可靠性价比高啊?

Andwhich company is a good choice for reliable quality and cost-effective?

螺旋桨涂装时要注意些什么?

Whatshould pay attention to when painting the propeller?

这一连串的问题也叫我这师父一时无从入手难以回答。毕竟螺旋桨喷漆不常见,大部分人不完全了解也很正常。现在拿徒弟提出的问题,给大家介绍下螺旋桨喷涂有机硅防污漆,有说的不对或需要补充之处请回帖!

Thisseries of problems also made me unable to know how to answer. After all,propeller spraying is not common, it is also very normal that most people donot fully understand. Now take my apprentice’s questions for example, I willintroduce the propeller spraying silicone antifouling paint, if I said thewrong or you want to supplement the department, please give me some replies!

船舶螺旋桨将推力传给船体本身驱动船舶航行,它是把船舶发动机产生的力矩转变成动能的重要部件。螺旋桨的重要性不用多说大家都知道,它的好坏直接影响整条船的工作状态。

Shippropeller thrust will be transferred to the ship itself and drive the ship,which is an important part that converts torque developed by ship engine intokinetic energy. The importance of the propeller is needless to say. And it hasthe most important effects on the work status of the whole ship.

螺旋桨是不是铜的?

船用螺旋桨主要材料是铜,但是根据不同的船型和需求。船舶螺旋桨铜的材料又分为锰青铜、镍锰青铜、镍铝青铜、锰铝青铜这四种!这里就不一一介绍这些材料的区别了。有兴趣的读者自己去找找相关资料,了解下!

铜质螺旋桨一般不会生锈那为什么还要喷漆啊?难道螺旋桨也需要防污漆的保护?

Isthe propeller made by brass?

Themain material of marine propeller is brass. But based on different ship typesand requirements, the material of the ship propeller is aluminum bronze. I willnot introduce their differences one by one. If you have interest, you may getsome relevant information to know about it.

Generally,brass propeller will not rust, but why painting? Does propeller also requirethe protection of antifouling paints? divided into four kinds, which are manganese bronze, nickelmanganese bronze, nickel aluminum bronze and manganese

不要以为螺旋桨主要成分是铜就不会长海洋生物,恰恰相反在船舶停航并且外部环境很适合海洋生物的生长(如夏季水温适宜、又地处江河湖等淡水入海口、营养化严重的水域、长期停航)。螺旋桨上生长的海洋生物会叫人难以想象。 Don’t think that propeller doesn’t grow marineorganisms because ofits main component of brass. On the contrary, when the ship is suspended, theexternal environment is very suitable for their growth (for example suitablewater temperature in summer, at such asrivers, lakes and other fresh water into the sea mouth, in severe-eutrophic water,and be long-term suspended). The growth of marine organisms on the propeller ishard to imagine.

照片里这条船是条新造船,下水后码头舾装到试航大概用了2个多月时间。在试航时发现航速严重不达标 (设计最高航速15节实际上拼尽全力也只能达到11节,这样的结果无论那个船东都是不能接受的) 、整船震动大、主机油耗超标等问题。导致试航失败!回航后进坞排查原因。

Theboat in the picture is a new ship, and it took about 2 months from outfittingto trial trip. On its trials run, some problems were found that the speed wassub-standard seriously (a designed maximum speed of 15 knots actually can onlyreach 11 knots, and this result was not acceptable), the entire ship hadvibration, and engine fuel use exceeded. The trial resulted in failure. Afterits return, it was docked for inspecting.

发现螺旋桨怎么和正常的螺旋桨不大一样,上面好像有很多的附着物! It’sfound that the propeller is abnormal because much dirt was attached on it。

整个螺旋桨上正面、反面、甚至桨尖上都不能幸免。长满了海洋生物~~~滕壶。螺旋桨的外形因为长满了附着物已经发生了改变,船舶的航速油耗受到影响也就顺理成章了。由此可见船舶螺旋桨的防污是多么的重要。

Boththe front and back walls are not immune, even the helical tip。They are covered bya marine organism named barnacle。Because of theattached plant, the propeller’s outline has changed, The navigational speed andfuel consumption rate would certainly be bad. Thus it can be seen thatantifouling for propeller was so important.

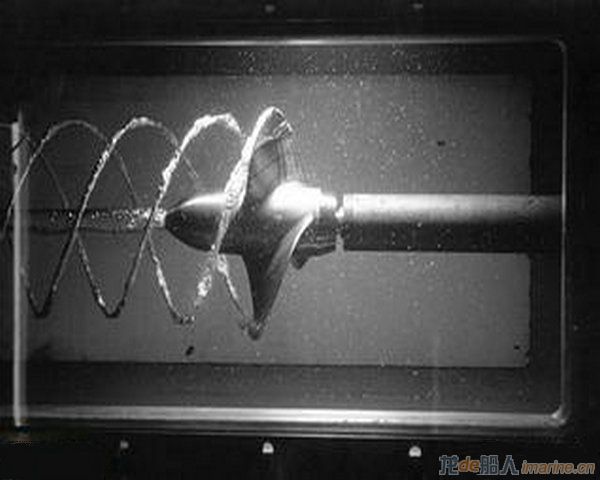

螺旋桨不会生锈但是会因为螺旋桨的空泡现象,对螺旋桨照成严重的侵蚀。船舶大型化和高速化使得螺旋桨负荷不断增加,尾部流场的不均匀性使得螺旋桨上产生时生时灭的空泡。由于空泡溃灭产生内爆,这种内爆之冲击力反复集中于一点,桨叶表面反复侵蚀后形成多孔的海绵状麻点。导致螺旋桨侵蚀损伤。

Whilecopper propeller does not rust, it also can be eroded seriously by cavitation. Forthe vessel are more and more huge and fast, the propeller’s load are addedaccordingly, the aft flow field to be more unstable, much cavitation will begenerated on the surface of propeller, they grow up and crush out. Forthe vessel are more and more huge and fast, the propeller’s load are addedaccordingly, the aft flow field to be more unstable, much cavitation will begenerated on the surface of propeller, they grow up and crush out. Thecrush of cavitation will lead an implosion, if the implosion force converge onone point repeatedly, some spongy pits will generated on the propeller bladesurface, result in a eroded damage.

空泡现象对螺旋桨的危害可见一般,母材受损照成螺旋桨原本光滑光顺的表面物理外形发生改变。船舶航速降低、主机负荷增加、油耗越来越严重。全新的螺旋桨每一片桨叶重量都是一致,经过动平衡和静平衡试验才能安装到船上。此时的螺旋桨到达最佳的工作状态。船舶航行一段时间,因空泡现象螺旋桨每一片桨叶都受到不同程度的侵蚀受损,重量发生了不同程度的改变。由于受空泡现象侵蚀后的螺旋桨每一片桨叶的重量各不相同,造成螺旋桨动平衡静平衡都随之发生改变。对船舶的主机和轴系都带来了很大影响。遇到这种情况只能进坞修理。轻者简单维修,重者直接报废更换新的螺旋桨。即使进行了维修,修好后经过一段时间的航行。螺旋桨还会因空泡现象螺旋桨再次侵蚀受损。船舶频繁进坞维修整个运营的成本攀升!

Therebyit can be concluded that the cavitation was so dangerous, if the base metal hadbeen damaged, the original smooth physical surface outline will be changed tounsatisfactory.

Thenavigational speed will be reduced, M/E load will be added, Fuel consumptionrate will be also added. For one new propeller, each blade hasequal weight, they are fitted on vessel under a reasonable dynamic balance andstatic balance test. Then the propeller can work in the best case. Aftera period of sailing, for the reason of cavitation, each blade was damaged in adifferent level, their weight changed different also, lead a unexpected changeof dynamic damage to the M/E and shaft system. In this case, the vesselshould dry docking repairs. In less severe case, a simple repair was necessary,in severe case, the propeller should be replaced. Even so, after a period oftime, the propeller will be damaged again. Obviously, so much drydocking repairs were expensive.

那螺旋桨上喷的是什么漆?

螺旋桨上喷涂的是有机硅防污涂料。

如果能在螺旋桨上做上弹性非常好表面非常光滑的有机硅涂料,能有效的防止螺旋桨的空炮侵蚀。当空泡现象发生时,螺旋桨流场爆裂的空泡产生的冲击力作用到有机硅涂层表面。有机硅涂层有其他涂料无法比拟的弹性,表面非常光滑会不断地缓冲这股冲击力。使得螺旋桨本身不会因为空泡现象而侵蚀。好比给螺旋桨穿上了一件由凯夫拉 ( KEVLAR ) 制成的防弹衣。保证了螺旋桨的正常工作状态。船舶的运营维修费用大大降低,经济性显著提高。

What’sthe paint spray on the propeller?

It’sorganosilicon anti-fouling coatings.

If the silicone paint sprayed on the propeller couldmake the surface of it smooth and elastic, the propeller can prevent the cavitation erosioneffectively. When the cavitation generating, the implosion force acton the organosilicon anti-fouling coatings surface, because of the goodelasticity, the implosion force will be cushioned, thus the propeller will beprotected. It is liked put a body armour made by KEVLAR on thepropeller, ensure a best work condition for it. The repair cost will be reducedgreatly and economical efficiency added remarkable also.

(中塗化工涂料CHUGOKU【CMP】 提供的资料照片)

(The pictureof information provided by CHUGOKU【CMP】)

(船舶螺旋桨做有机硅防污漆航行23个月后对比照片)

(The sailing shippropeller do silicone antifouling 23 months later before-and-after photos)

(船舶螺旋桨做有机硅防污漆航行32个月后照片) (The picture of shippropeller make silicone antifouling 32 months after sailing)

据中塗化工涂料CHUGOKU【CMP】 提供的资料,螺旋桨上涂有机硅涂料能有效的阻隔空泡侵蚀,螺旋桨使用年限对比没有涂有机硅涂料的提高数倍.

Accordingto the information of CMP, Propeller on coated organic silicone coating caneffectively block the cavitation erosion,The time of years that propeller can use isseveral times higher than that of without painting organic silicone coating.

船用螺旋桨喷涂的主要涂料是有机硅防污漆。与传统的防污漆不同,有机硅防污漆防污机理完全依赖涂层表面非常光滑。海洋生物无法附着到光滑的表面,即使附着上也无法立足生长。而传统自抛光水溶型防污漆,是通过基料与海水反应和溶解,通过毒素渗析杀死海洋生物达到防污的目的。

Marinepropeller spraying coatings are mainly organic silicon antifouling paints.Different from traditional antifouling paint,Silicone antifouling paint’s antifoulingmechanism completely depend on the coating surface which is very smooth,The surface of the sea creatures can’t attached to the smooth,Even attach it cannot based on growth. Since the traditionalpolishing type water soluble antifouling is through base reaction with waterand dissolve,By toxins kill Marine life to achieve thepurpose of antifouling dialysis.

有机硅防污涂料也可以作为整船的防污涂料来使用,它有以下特点: Silicone antifouling paint can also be used as the ship of antifouling paint has the following features:

1.无毒。由于低表面能涂料的作用机理没有化学因素,因此有机硅涂料不含任何毒料如:氧化亚铜、有机锡或者其他杀

虫剂!不受当前国际海洋环境法规和公约的限制。是目前最环保的防污漆。

1.Non-poisonous. Dueto the low surface energy coating mechanism of no chemical factors, Organic siliconcoating does not contain any toxic materials such as: cuprous oxide、Organic tin or other pesticides!Not limitedby the current international Marine environmental regulations and conventions. Sothis is the most environmentally friendly antifouling paint.

2.自抛光。有机硅防污涂料涂层表面非常光滑不粘海洋生物,即使附着上只要船舶达到一定航速,表面就可以自行清洁。海洋生物很容易就被水流冲刷掉。始终保持涂层表面光滑性。

2. Self-polishing. Silicone antifouling paint coating surface is very smoothand not sticky of Marine biology,Even attach as long asthe ship reached a certain speed, the surface can clean itself. Marine life iseasy to wash away by water. Always keep the coating surface smoothness.

3.有机溶剂(VOC)含量低,低表面能有机硅防污涂料一般固体含量都超过70%。VOC含量很低,对施工人员的身体健康和和环境负面影响都很小。 3.Organic solvents (VOC) content is low,Generally low surface energy silicone antifouling coatings this more than 70%. With is low content of VOC,it has little harm to the wokers’health and the environment.

4.保护周期长。有机硅防污涂料一般的有效期为5年,5年以后,由于使用中有一定的损伤需要重新修补。修补后有可获得5年的有效期。一般的船舶寿命大概在25-30年。也就是说在整个使用寿命中做5-6次涂层修补即可。 4.The cycle of protect is long. Silicone antifouling coatings in general will be valid for 5 years,5 years later,Due to the certain damage of using needs to be repaired. The validity of the repair can be obtained after 5 years. The lifetime of the ship is 25-30 years in genneral. That is to say, it only have to do 5-6 times coating repair in the whole service life of the ship.

5.节能经济。由于船舶使用了有机硅涂料防污,涂层表面非常光滑。有资料表面如果整个船底都采用有机硅防污涂料,能节约燃油5%甚至有的船型能打到6%以上。特别是如果螺旋桨采用有机硅涂料大大降低了空泡现象对螺旋桨的侵蚀,保证了船舶最佳的航行状态。经济方面得到了很大的提升。

5.Energy-economy. Becauseof using the organic silicone antifouling coatings,The coating surfaceis very smooth. Data indicated that if the entire bottom using siliconeantifouling paint can save fuel above 5%-6%. If the propeller using siliconecoating, Cavitation erosion of propeller is reducedgreatly to ensure the best state of navigation of the ship. It is benefit forthe economic growth.

哪家油漆公司的有机硅涂料质量可靠性价比高啊?

Whichpaint company silicone coating quality reliable and cost-effective?

目前国际上比较著名的几大油漆公司中塗、国际、佐敦等都有此类产品推出。在实际应用中中塗化工CHUGOKU 【CMP】的有机硅涂料质量有保障价格相对适中。很多大型国际航运公司都在采用他们的产品。

Currently,most famousinternational paint company such as CMP, IP, Joton, etc. Have such productslaunched. In practical application the silicone paint produced by the chemicalindustry CHUGOKU [CMP] has a high quality and a reasonable price. Many biginternational shipping companies are using their products.

螺旋桨喷涂有机硅防污涂料施工时要注意些什么?

Whatshould be paid attention to when the propeller is sprayed with silicone antifouling painting?

有机硅防污涂料表面能非常低,其对基材结合力不是很好。故对整个涂装施工过程要求非常严格。下面我就用中塗化工CHUGOKU 【CMP】的有机硅防污涂料的技术要求,来给大家讲一下有机硅防污涂料涂装施工注意事项!

Siliconeanti fouling painting has a very low surface energy and can be well binded withthe base material.so the whole process of painting has a very strictrequirement. Now I will take the CHUGOKU[CMP] silicone anti fouling paintingfor example to introduce the technical requirements when painting and giveyou a talk about what should take into considerationwhen use the silicon anti fouling painting.

1. 涂装施工前对螺旋桨表面进行高压淡水清洗清洁。

螺旋桨在加工和安装过程中有很多的抛光膏、油污、不容易除去的灰尘颗粒等不利于涂装的表面残留。这些残留必须彻底清除。先用高压淡水清洗除去螺旋桨表面的灰尘污垢和微量盐分。再用稀释剂擦拭清洁表面的油污,抛光膏等残留。

1.The propeller surface should becleaned with high pressure freshwater before spraying painting. In the processof making and install the propeller, it has a lot of polishing paste, oil, dusthard to remove, which is harmful to the spray process, so the residues on thesurface of the propeller should be removed absolutely. First, remove dirt andsalt from the surface of the propeller by using high pressure fresh water, thenwipe the polishing paste and other residues on the surface with diluent.

(清洁前螺旋桨照片)

(The picture of propellercleaning before)

(清洁后螺旋桨照片)

(The picture of propellercleaning after)

2. 螺旋桨喷涂有机硅防污涂料前,邻近区域的漆膜应充分保护。并同时搭设施工防护棚。

有机硅防污涂料施工过程中,要求对周围环境严格保护。不能污染其他区域。有机硅防污涂料成膜后,表面非常光滑、不粘性极强,很难和其他油漆融合。一旦飘落到其他油漆表面必须进行彻底的清除否则将不法进行复涂。所以必须对其他油漆表面进行细致彻底的保护。搭设防护棚一定要做到全覆盖无缝隙!

2.The paint film of the adjacent areashould be fully protected before the propeller is sprayed with silicon antifouling paint and to build a protective shed when painting at the same time.

Inthe process of spraying silicone anti fouling paint, the surrounding of theenvironment needs strict protection and other areas can not be polluted. Afterthe silicon anti fouling paint film is formed, the surface is very smooth, nothighly viscous and it is difficult to blend with other paint. Once falling downto the other paint surface, it must be completely removed or it should notcarry out the repainting. So it is necessary to protect the surface of theother painting carefully and thoroughly. The shelter must be fully covered thepropeller with no gap.

(对螺旋桨相邻油漆表面保护照片)

(The picture of propelleradjacent paint surface protection)

(螺旋桨搭设防护棚照片)

(The picture of propellerbuild-up protective casing)

3.冲砂

铜质螺旋桨冲砂时必须采用非金属磨料。如果用金属磨料如钢砂冲击铜质螺旋桨会在铜表面上残留,会与铜发生电偶腐蚀。铜质螺旋桨冲砂时必须采用如棕刚玉、石英砂、石榴石等非金属磨料。磨料尽快能采用14—16#。冲砂表面要达到粗糙度35—65微米。

3. Sand washing

Non-metal abrasive should be adopted when copperpropeller is sand washing. If such as metal abrasive is used in sand washing, itwill remain on the surface of the copper propeller, then galvanic corrosionwill occur with Cu. When the copper propeller is sand washing, such as regularfused alumina, quartz sand, garnet and other non-metallic abrasive must beused. Abrasive can be used as soon as 14 – 16#.After the process, the copperpropeller surface roughness should reach 35 – 65 um.

(石英砂磨料照片)

( The picture of Quartz sand abrasive)

(冲砂后螺旋桨表面有夹砂现象照片)

( The picture of propeller surface after sand washing sand inclusion phenomenon )

(螺旋桨冲砂后手工砂纸打磨前后对比照片)

(The picture of Screwsand washing after manual comparison before and after sanding)

冲砂后螺旋桨表面会有很多的灰尘和磨料的残留。有机硅防污涂料系统对表面清洁要求很高,这些必须清除干净。要用砂纸进行手工打磨以除去这些不好清理的残留。并用高压风进行细致吹尘。

There will be a lot of dust and abrasive residueon the surface of the propeller after sand washing. The silicone anti foulingpainting system needs high requirements on the surface’s cleanliness, So theseresidue must be cleared. To use sandpaper polished to remove these residuesthat hard to cleaning and use high pressure air to blow away the dustcarefully.

(螺旋桨冲砂后有油污残留照片)

( The picture of afterthe screw sand washing oil residue )

对于一些残留的油渍,也要用稀释剂清洗干净。

Someof the remaining oil also needed to use thinner to clean.

(螺旋桨喷漆前最后一道清洁照片)

( The picture of propellerlast cleaned before painting )

最后对整个螺旋桨做喷漆前细致的清洁,确保所有螺旋桨表面都符合施工要求。并请油漆技术服务商进行过程确认。

Finally,the whole propeller should be cleaned carefully before painting and to ensurethat all the surface of the propeller are in line with the requirements of theconstruction and to confirm the process with paint technical service providers.

(螺旋桨冲砂合格准备喷漆注意照片里的其他油漆表面的保护)

3. 喷漆。 3. Painting

第一道漆为丁醛树脂基蚀刻底漆。主要功能就是封闭铜表面,增加与下道涂料的附着力。

The first paint is butyraldehyde resinetch primer which main function is to seal the surface of copper and increasethe adhesion with the next。

(第一道油漆照片)

(Paint picture for the first time)

(第一道油漆喷漆过程中照片)

(The picture of paint spray painting process for the firsttime)

第二道漆为改性环氧漆中间漆,作为配套CMP BIOCLEAN防污体系的底漆。要提前做好预涂,并在喷涂前做好表面清洁。选用技术水平高的枪手,确保一次喷漆达到规定漆膜厚度。尽可能避免漆膜的二次修补。

Thesecond paint is modified epoxy intermediate paint which is used as the primerof the CMP BIOCLEAN antipollution system. It must be pre-painted in advance andkeep the surface clean. Skilled painting worker should be chosen and ensurethat the thickness of the paint film reach the required standard. Try the bestto avoid the second patch of paint film.

(第二道油漆预涂照片)

(The picture of secondpaint coating)

(第二道油漆照片)

(The picture of thesecond paint )

(油漆技术服务商会对第二道油漆膜厚进行严格检验的照片)

(The picture of painttechnology services chamber of commerce inspect the second oil film thickness)

第三道漆为有机硅防污漆,这道漆至关重要。它施工的好坏也直接影响这个涂装质量。要求也十分的苛刻。由于有机硅防污涂料表面光滑,机械结合力很弱。涂装间隔就显得尤为重要,一般的情况下油漆技术服务商都会要求在4-8小时之间就进行复涂。只要中间漆表面固化,就可以进行复涂以增加油漆层间化学分子链的结合。有机硅防污涂料,不可以和其他油漆混合。所以在进行有机硅防污涂料施工时所用的工具,必须是全新或者是仔细清理过的。

Thethird paint is silicone antifouling paint which is the most important part inthis process. The construction quality has a direct impact on the quality ofpainting. The requirements are also very harsh. Because of the siliconeantifouling coatings with smooth surface, mechanical binding force is veryweak. So the time between the painting is important, under normalcircumstances, the paint technology service providers will required the secondpainted in 4-8 hours. As long as the middle of the paint surface curing, the secondpainting can be carried out to increase the paint layer between the chemicalmolecular chain combinations. Silicone anti fouling paint can not be mixed withother paint. So all tool used in the construction of silicone anti foulingpaint must be new or carefully cleaned up.

(滚筒和装油漆小桶照片)

(The picture of rollerand paint small bucket)

刷漆用的滚筒、装油漆的小桶必须是全新的。

Paintbrush, paint roller of little barrel must be brand new。

(喷漆泵吸口照片)

(The picture of spraypump suction)

喷漆泵的吸口一定要加装全新的过滤网,吸口软管也要替换成新的。

Spraypump suction must be equipped with a new filter, Suction hose is replaced withnew one.

(搅拌器照片)

(The picture of agitator)

搅拌器经过仔细清理不能有其他油漆残留。

Blenderafter careful cleaning cannot have other paint residue.

(喷漆枪带照片)

(The picture of spraygun belt)

喷漆枪带一定要是全新的,以免油漆在枪带中受到污染。喷漆泵要经过多次清洗,将喷漆泵里残留的其他油漆全部清洗干净。

Spraygun belt must be new in order to avoid the pollution of the paint in the gunbelt. Spray pump should be wash many times, The remaining paint spray pump shouldbe clean up.

(喷漆枪和枪嘴照片)

(The picture of Spraygun and the gun mouth)

喷漆枪和枪嘴也必须是全新的。枪嘴采用17B25.

Spraygun and the gun nozzle must be brand new. Gun nozzle using 17 B25。

(整体喷涂前试枪照片)

(The picture of Overallspray gun before try)

喷漆枪手一定要挑选做过特涂 、有经验、水平高的枪手。在喷漆过程中一定要保证高压空气的压力。确保一次性喷涂成功。在正式喷涂有机硅防污漆前一定要枪手试枪。直到确认调试好设备才能进行喷涂作业。

Thespraying worker must select who had a special painting, a high level ofexperience. To ensure that the pressure of high pressure air in the process ofpainting and spraying success in one time .The worker must test the paintinggun before the formal spray silicone anti fouling paint.

结束语

由于有机硅防污涂漆施工难度大、技术要求程度高、价格是普通的防污漆几倍。所以它的推广应用势必困难,但它的优良性能大家也是有目共睹。不少明智的船务公司还是在不断的采用有机硅防污漆,为船舶的螺 旋桨甚至整个船体提供防污保护。

Theending

Itis difficult to promote the application of silicone antifouling paint for it ishard to construction and it needs high painting skill and the price is severaltimes than ordinary antifouling paint, but its excellent performance is obviousto all of us. Many wise shipping companies are still use silicone antifoulingpaint to protect the propeller of the ship even the ship body from thepollution.

一般船东不用有机硅防污漆。(工薪型船东)

General owner without siliconeantifouling paints(Working model of the owner)

明智船东用有机硅防污漆对螺旋桨进行防护(老板型船东) Wise owner withsilicone antifouling paint for protection propeller(Theboss type of the owner)

有钱的船东不但做了螺旋桨顺带把舵页也给做上有机硅防污漆(大款型船东)

Richowners not only do the propeller by jerked the page also to do siliconeantifouling paint(the rich owner)

啥也不说了老子不差钱,整个船底全做有机硅防污漆(土豪型船东)

The entire bottom do silicone antifouling paint(thewealthy owner)